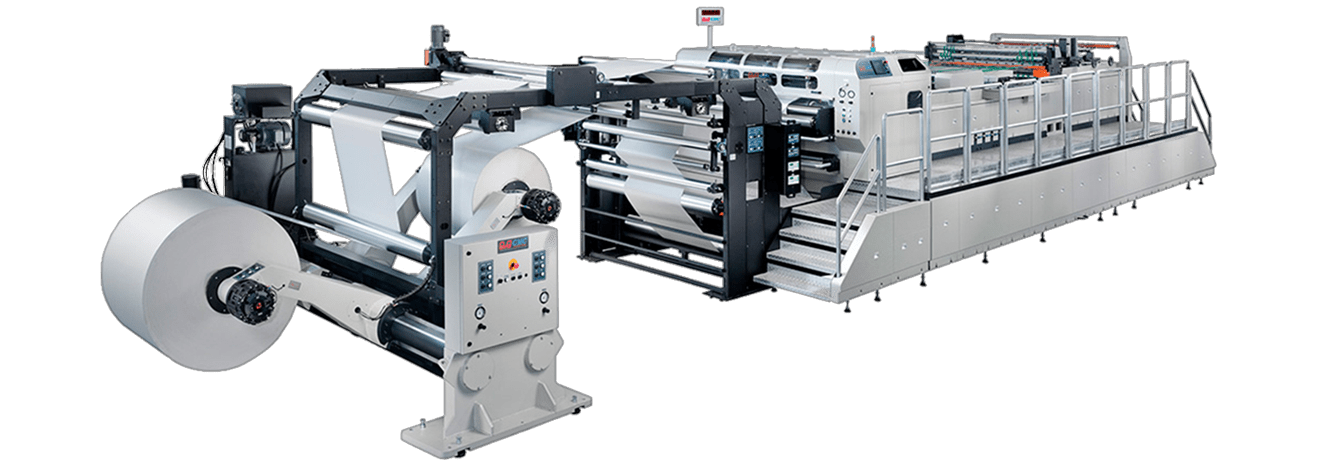

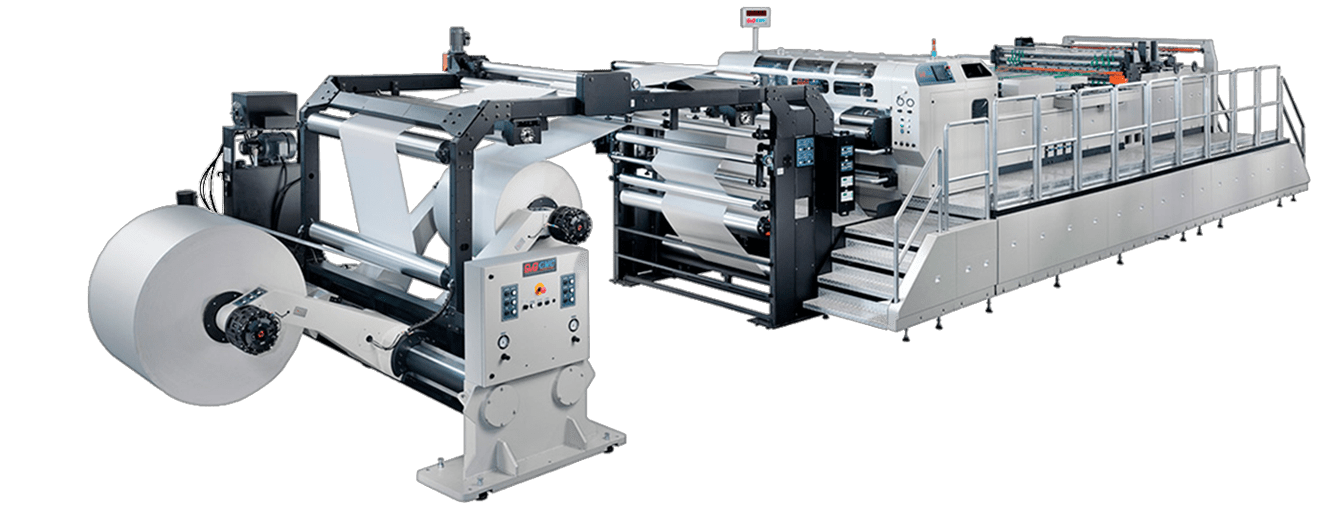

The High-End Paper Sheeter Machine

The Goodstrong 1650 paper sheeter machine is our new high-end machine for all your paper sheeting requirements. It features a new cutter head design to give your equipment an increased speed curve and in turn increase production for your business. As the higher-end model of sheeting equipment, it also comes standard with extra options as well as an upgraded overlap and stacker section of the machine. All these improvements combined with the efficient standard sections of your equipment guarantee that your paper sheeter machine will improve your workflow.

Specifications:

- Max. Cut Frequency Cutting curve up to 350 m/min (1150 ft/min)

- Min. – Max. Web Width 400 mm – 1,650 mm (16” – 65”)

- Min. – Max. Slit Width 280 mm – 1,650 mm (11” – 65”)

- Knife Loading 1000 gsm (200 lbs/1000 sq. ft.) or (600 lbs/3000 sq. ft.)

- Material Paperboard, coated & uncoated (C1S and C2S)

- Cut-off Length Range 400–1,778 mm (16” – 70”)

- Max. Lifting Table Height 1600mm (63”) (including pallet)

- Max. Skid Weight 2,500 Kg (5,500 lbs)

- Accuracy Single web +/- 0.38 mm (0.015”), Multiple webs +/- 0.50 mm (0.020”)

- Main Power 3 Phase, 480 V, 60 Amp, 60 Hz

- Power Consumption 55 KW

- Max. Roll Diameter 1900 mm (73”) – (81” optional)

- Max. Roll Width 1650 mm (65”)

- Max. Weight 3200kg (7,000 US lb) (per reel)

- Core Chucks Ø 3-6″ and Ø 10-12″ standard, 8” and 16” adaptors optional

Shaftless Dual Position Pivoting Arm Roll Stand

- Two 15 ft section of track and trolley, one per roll position with lateral side shift capabilities

- Taper multiple size ribbed chucks (Ø 3-6, Ø 10-12” and optional 16” or 8”)

- Renova Pneumatic air-cooled disc brakes on each arm

Web Conditioning

- RE Electric control Offset Pivot Edge guide for web control

- Four decurlers each with two different decurling bar diameters

- Two roll diameter tension control systems

Dual Rotary Knife Section

- Upper and lower helical knife cylinders cartridge

- Computerized motion controller for cutting length control

- Touch Screen (HMI) with order entry and diagnostics

- Brushless AC servo motor and PWM drive for knife cylinders

Conveyor Device

- Take-way belt section

- Reject gate

- Anti-Static device

- Adjustable sheet hold down vacuum system

- Sheet over-lap catch wheel assembly

- Top driving belt over overlap (10 plus belts with easy side shift capability)

- HMI Dual speed control for sheet over lap or straight out (single file)

Delivery section

- Hydraulic scissors lift table with safety catch feature

- Top driving belt over piler (4 belts, with manual side position shift, fine paper only)

- Side joggers with adjustable air vibrators